The Boundary Diagram: Better System and FMEA Design with Block Diagrams

1. Purpose (Why?)

Developing one or more boundary diagrams together with the responsible experts, before starting the system and FMEA design and as preparation for the respective object of analysis. This diagram form has proven to be the ideal tool for preparing FMEAs.

The Boundary Diagram is used to define the system to be analysed. This is done by making the necessary decisions about the location of the external interfaces. Those who define interfaces by and large define the system. The system definition also includes the determination of the inherent subsystems and their internal interfaces. With these, a further objective is also realised: Preparing the functional analysis. The interfaces represent the locations of the functions.

2.Procedure (How?)

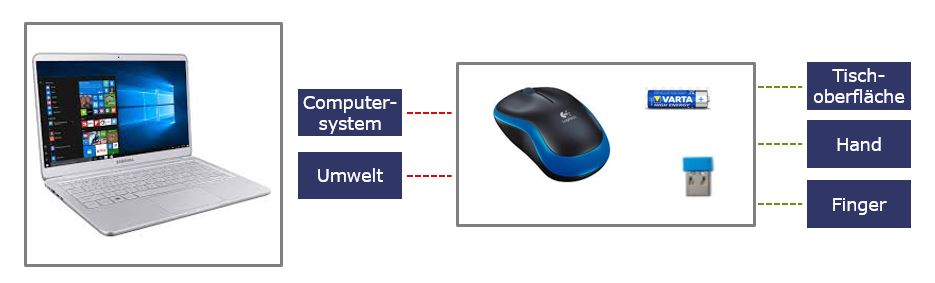

- Give the system a name. For instance: Cordless mouse.

- Define the associated development and/or delivery scope. For instance: Cordless mouse, USB plug, battery.

- Display and delimit corresponding but not associated systems. For instance: Notebook.

- Identify and document the external interfaces. For instance, the interfaces.

a. Cordless mouse/computer system

b. Cordless mouse/hand

c. Cordless mouse/table surface

d. Cordless mouse/setting

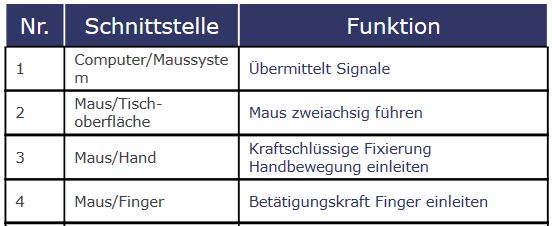

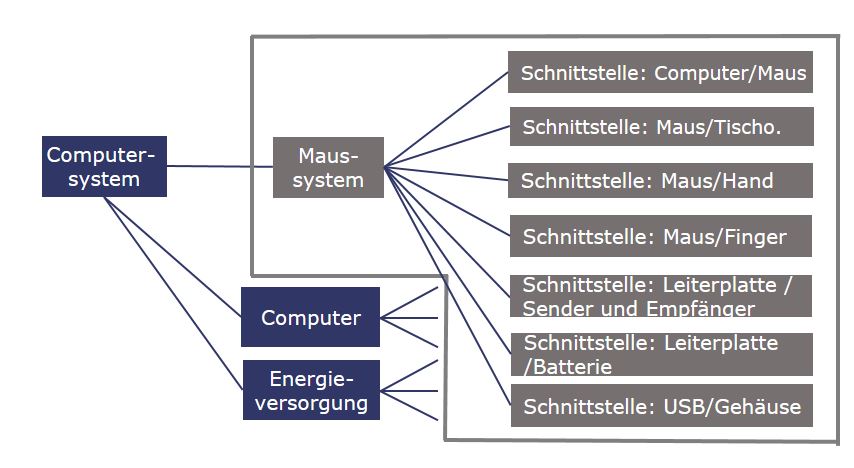

Fig 1. Boundary diagram: defining interfaces using the example of the wireless mouse. (Source: Dietz Consultants) - Create a table of the external interfaces with the corresponding functions.

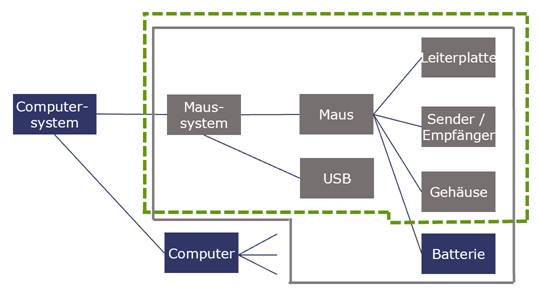

Fig 2. Boundary diagram: creating a function matrix using the example of external interfaces. (Source: Dietz Consultants) - Represent the inherent systems in the boundary diagram. For instance: Battery, circuit board, etc.

- Identify and document the interfaces of the inherent systems. For instance, the interfaces

a. Printed circuit board / housing

b. etc. - Create a table of the internal interfaces with the corresponding functions.

This information can now be used for the following steps in FMEA development: Define Application Area, Develop System Structure, and Perform Functional Analysis.

3. Result

The result indicates many discerning discussions of the FMEA team regarding application area, system structure and functional analysis which can be moderated safely and are at disposal of FMEA development as input variables.

It is also possible to use the interfaces themselves as system elements in the FMEA system structure. Thus a functional analysis can be realised, which can be well developed.

The visual representation of the development and delivery scope can be provided, in case they differ from each other.