Efficiency Filter FMEA

Challenge / Task

FMEA ties up the working time of experts for product development and process planning. This target group is already a “bottleneck resource” for other reasons. Therefore, it is extremely important to handle the “deployment times” of these people carefully.

What and How?

It is important to develop the P FMEA from a clearly defined role. Different roles lead to differences in the content of the P FMEA. The prevailing role can be “plant operator”. Other conceivable roles could be, for example:

- Factory planner

- Plant developer

- Technical cleanliness officer

- and many more

What:

- In the P FMEA, the roles of plant operators and developers are often mixed.

- Systematic industrialization concepts are also analyzed.

- Mixing these perspectives leads to erroneous P FMEA and unnecessary time expenditure.

How:

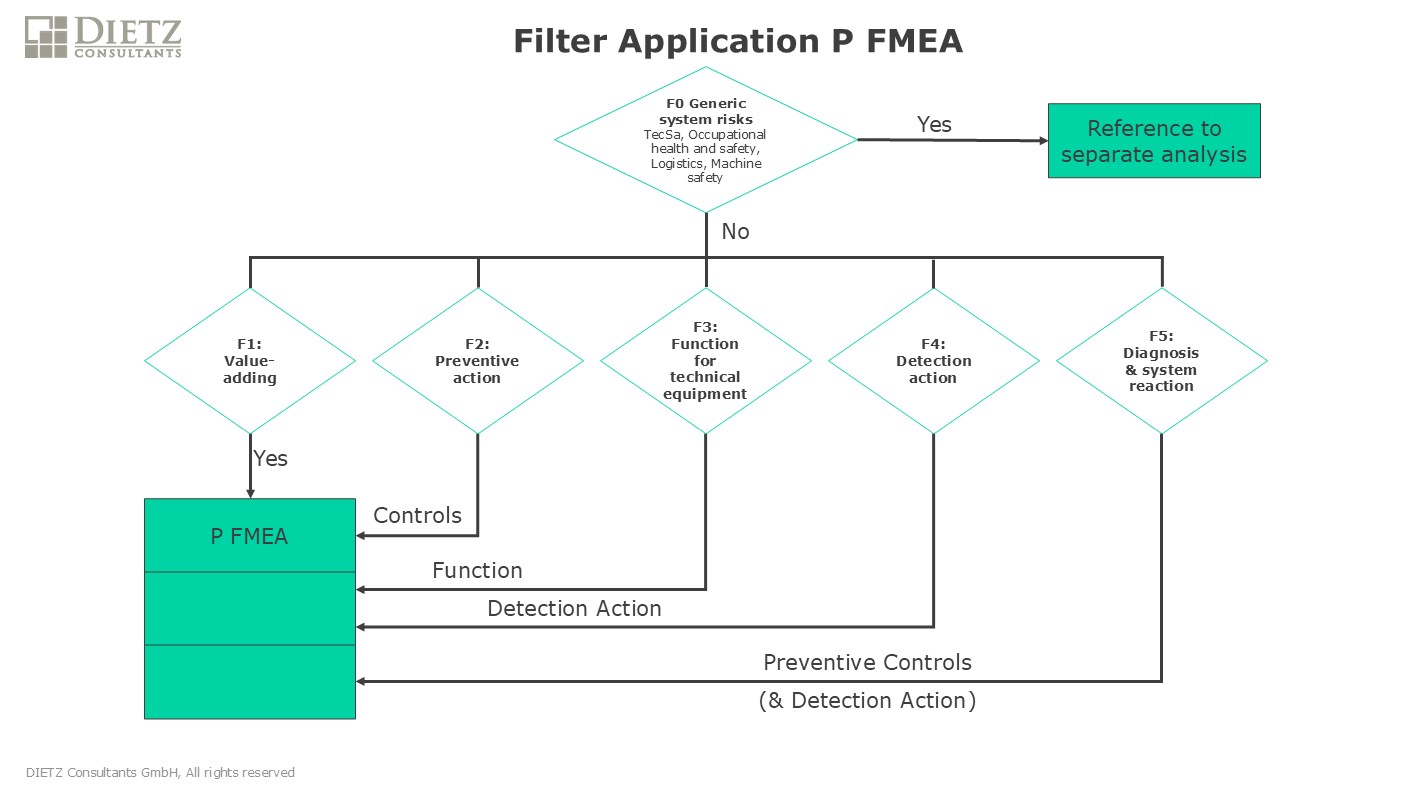

We recommend the use of efficiency filters for the preparation and execution of P FMEA.

This method helps to streamline the process and improve accuracy. It is explained below:

The Method:

Filter 0: Filter out overarching topics (e.g., safety, machine safety) to avoid double analyses.

Filter 1: Identify value-adding processes and analyze them with P FMEA.

Filter 2: Consider operating elements (e.g., maintenance) as apreventive controls in the P FMEA.

Filter 3: Analyze device functions as potential failure causes in the value-adding FMEA.

Filter 4: Analyze inspection processes as detection controls.

Filter 5: Analyze integrated diagnostic and system reactions both as preventive and as detection controls in the P FMEA.