FTA fault tree analysis part II

1. Objective (why?)

Methodology

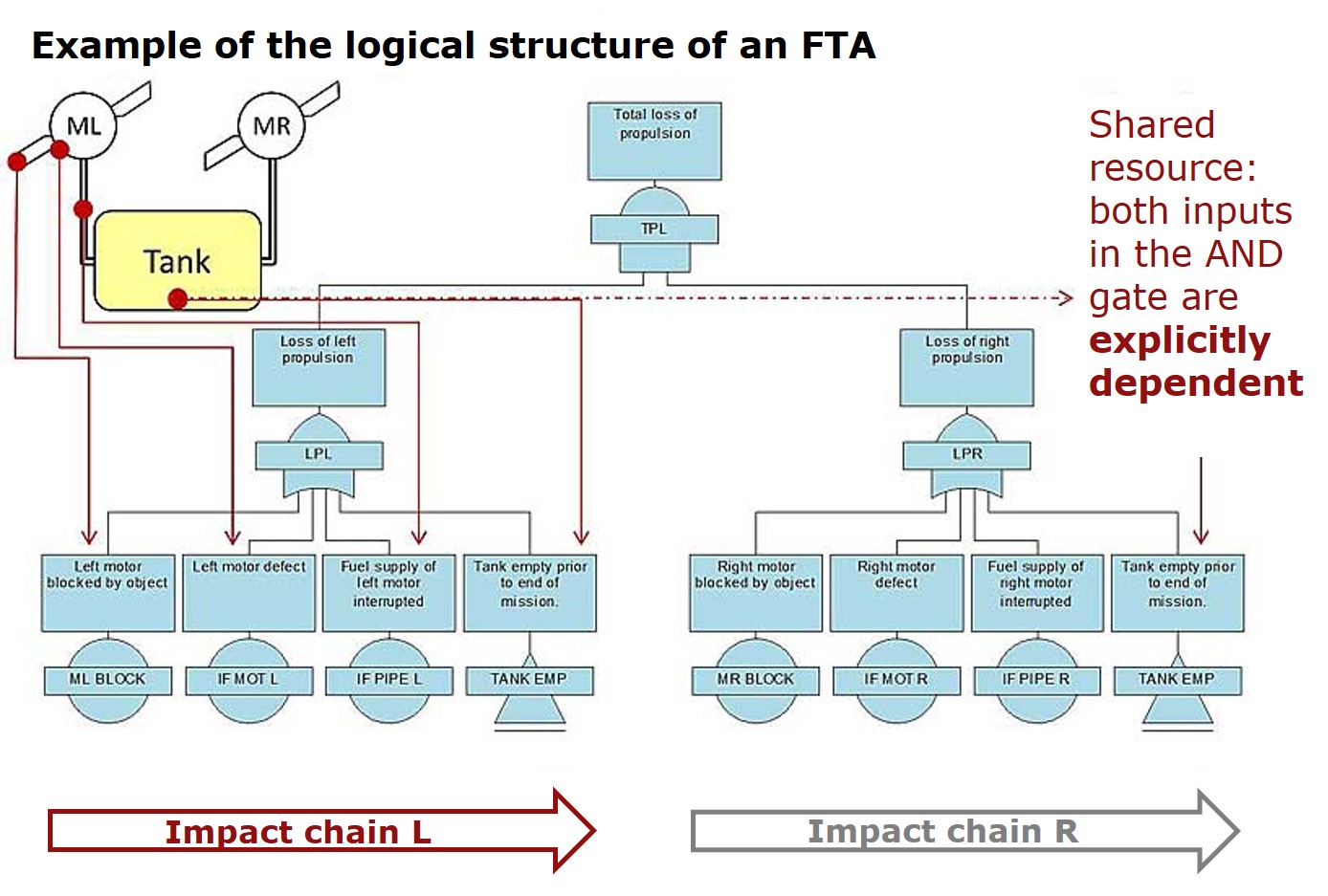

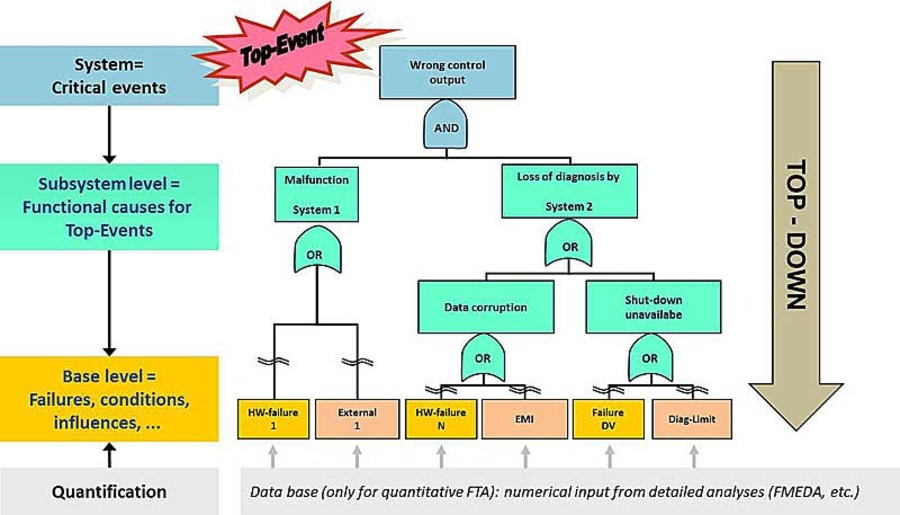

The method makes it possible to penetrate various abstraction levels for a system, from the overall behavior and functional architecture to the design.

The special feature is the graphic combination logic, which also takes into account multiple failures. This depiction is easy for engineers and technicians to understand.

Application failures

By incorporating technical reliability data (e.g. for HW components), the likelihoods of occurrence for the investigated top events can be predicted, even for complex and redundant systems. FTA also allows various systems or variants to be compared, which can provide an early basis for decision-making for development.

The method has thus already become firmly established in sectors such as aerospace or nuclear technology. This is also anticipated to take place in other sectors. This trend can currently be seen in the automotive sector, where more and more safety technology with complex electronics is being implemented while the requirements on safety evidence are also growing, especially as part of ISO 26262.

Like FMEA, the FTA methodology is very flexible and allows a wide range of problematic failures to be investigated. This means it can be used across technologies in the same way as FMEA. The method also requires suitable SW tools to control large quantities of information and perform the combinatorial probability calculation.

Like a modern FMEA, FTA also offers a tabular evaluation alongside the graphic presentation of failure behavior.

Special features of FTA include the minimal cut set and import analyses, which allow weaknesses and opportunities for optimization to be identified and prioritized for architecture and design.

Here is a brief explanation of two important metrics:1. Fussell-Vesely importance

- Measures the contribution of the observed failure to the top event

- This makes it possible to estimate for which individual failure a reduction in the likelihood of occurrence is most effective (to increase reliability)

- Allows the most important individual contributions towards the likelihood of the occurrence of the top event to be identified

2. Birnbaum importance

- Measures the likelihood of occurrence of the top event if the observed failure has already occurred

- Allows critical individual failures to be identified

- This makes it possible to estimate for which individual failures additional protective measures are most effective (redundancies, increased diagnostic coverage, etc.)

2. Procedure (how?)

As powerful as a methodology is – whether it is applied correctly is down to the user. It can be observed in practice that many of those using FTA lack sufficient basic knowledge. This concerns the mathematical and reliability-based background as well as the ability to perform understandable modeling.

In contrast to FMEA, where moderators and developers have a wide range of training, further training and current literature at their disposal, there is currently still a need for action when it comes to FTA topics.