Methodology of the Parameter Diagram (P-Diagram)

1. Objective (Why?)

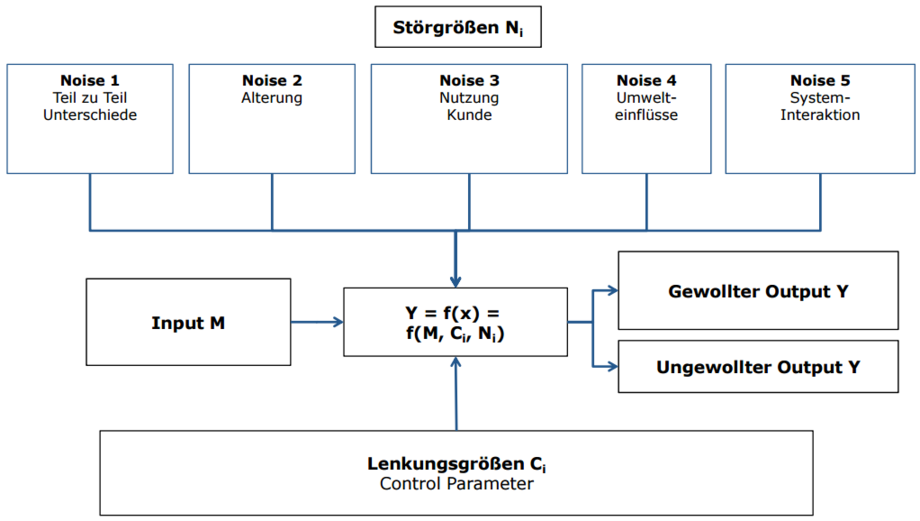

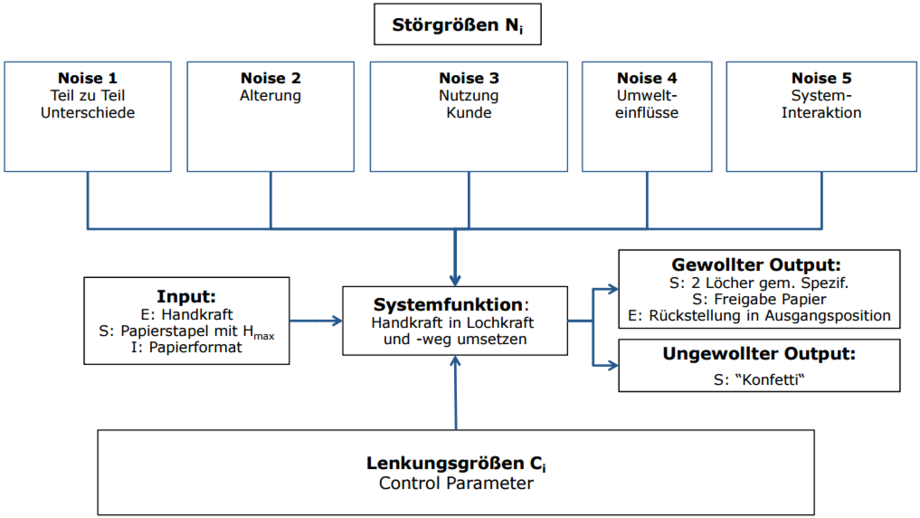

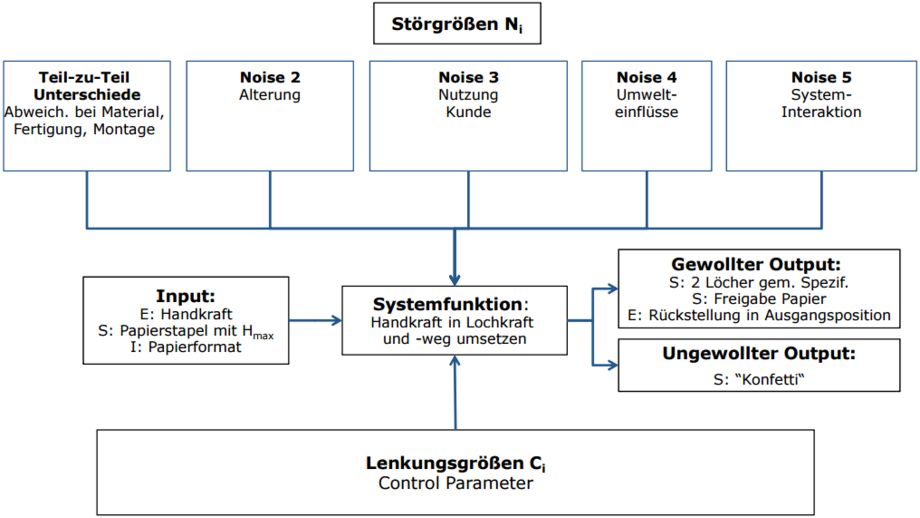

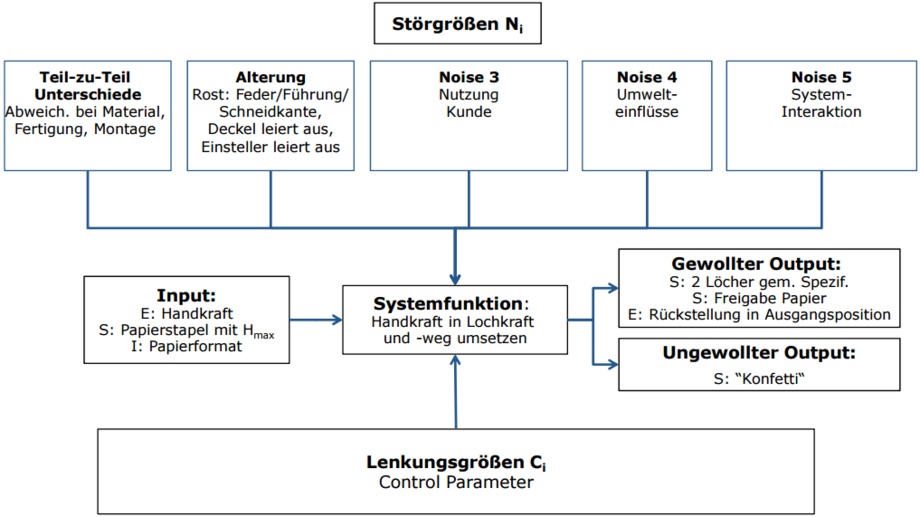

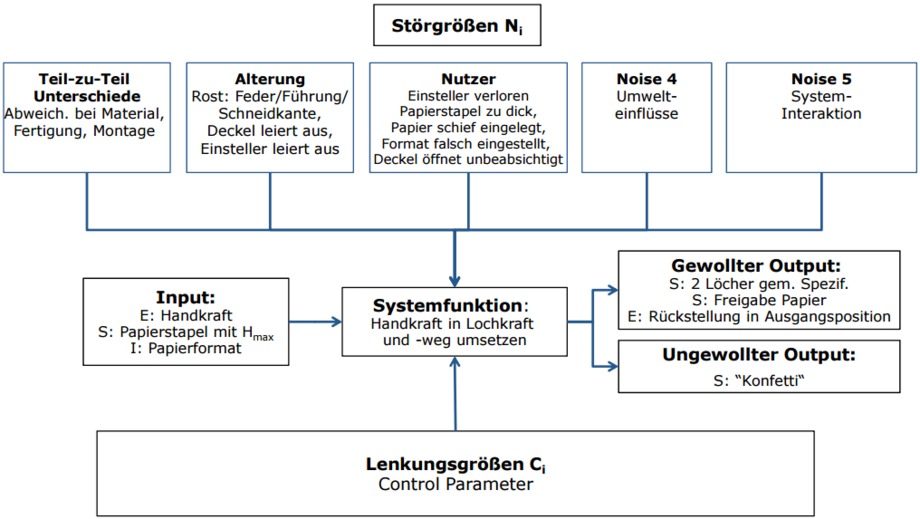

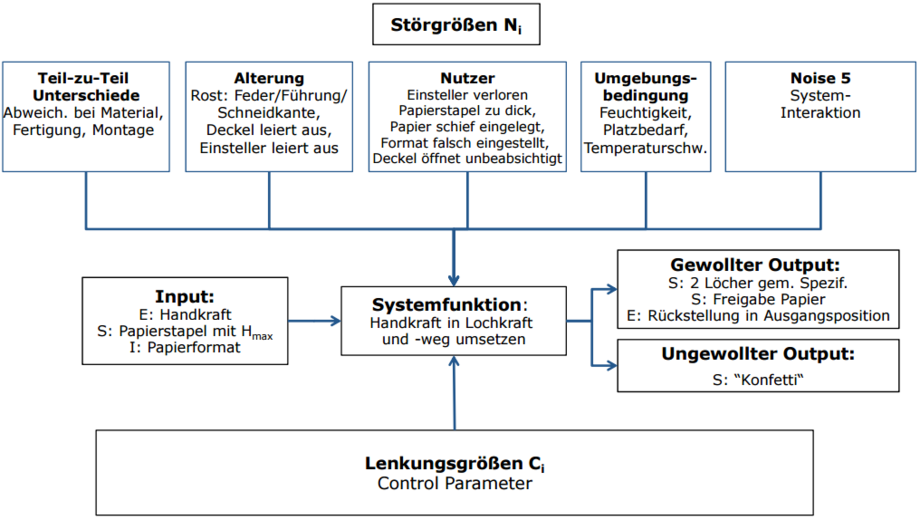

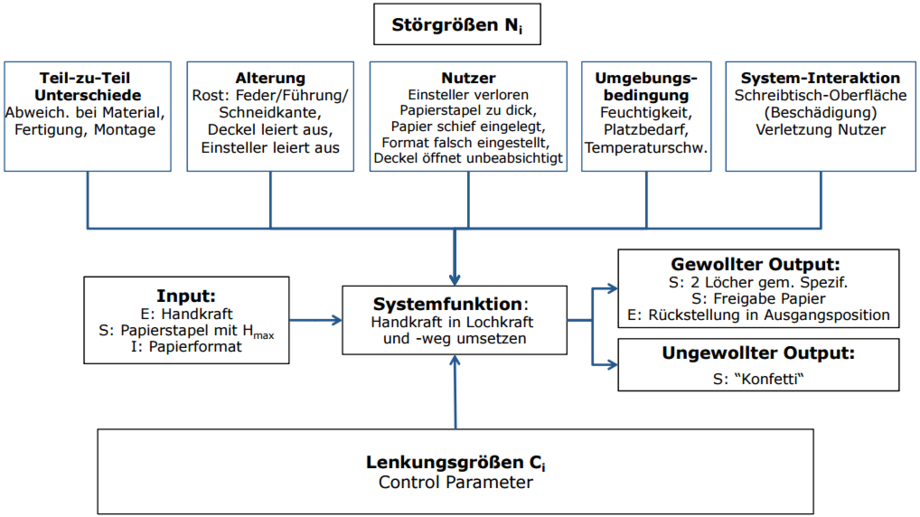

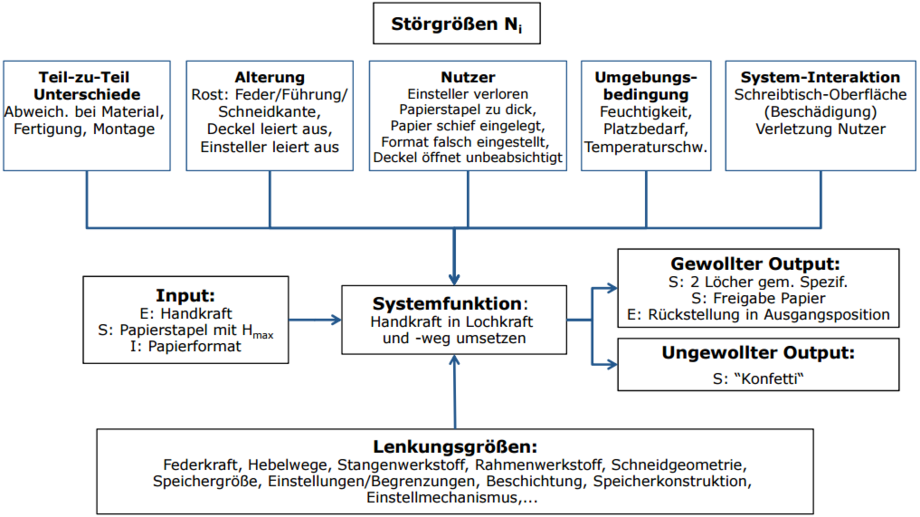

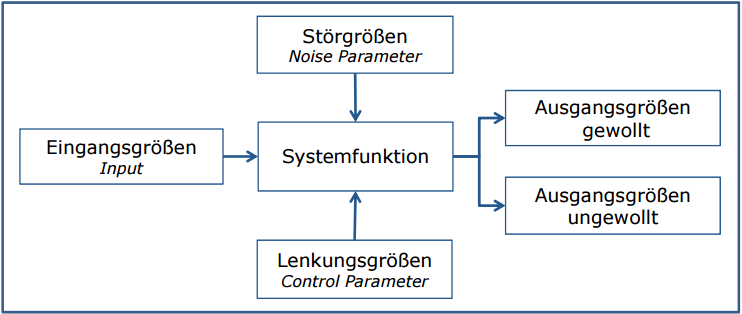

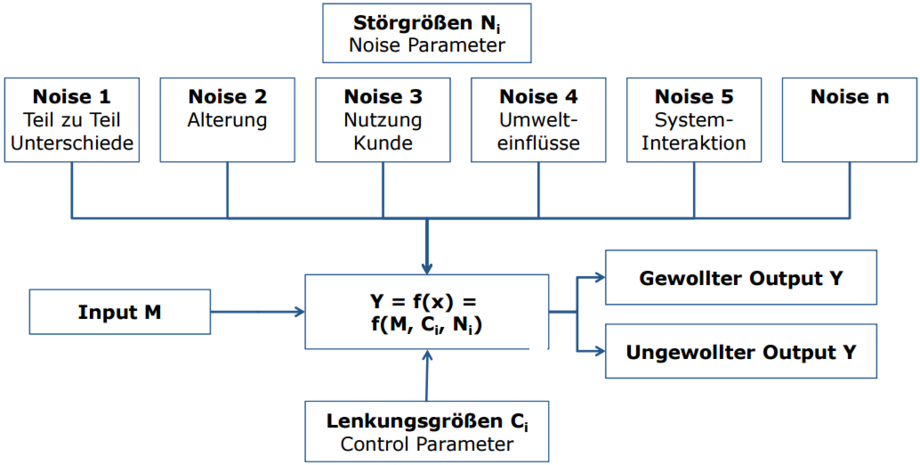

The Parameter Diagram (P-Diagram) is ablock diagramwhich shows the connections between differentparameters of a system.

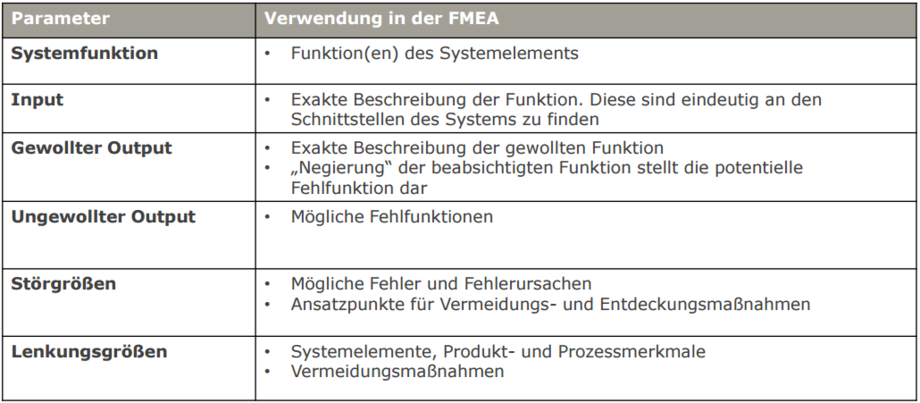

It is the ideal starting point of the FMEA: System elements und their functions aredescribedandvisualizedin a simplistic manner

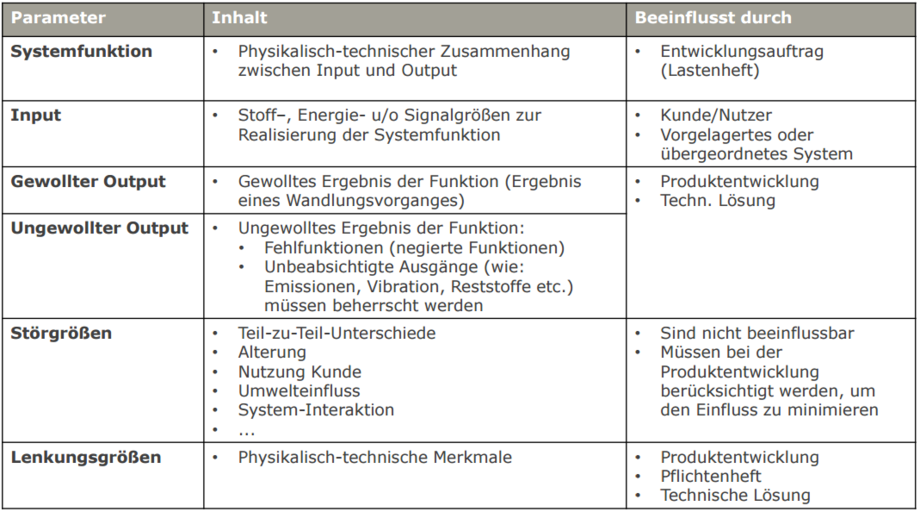

The P-Diagram includes the followingcomponents and relations:

2. Procedure (How?)

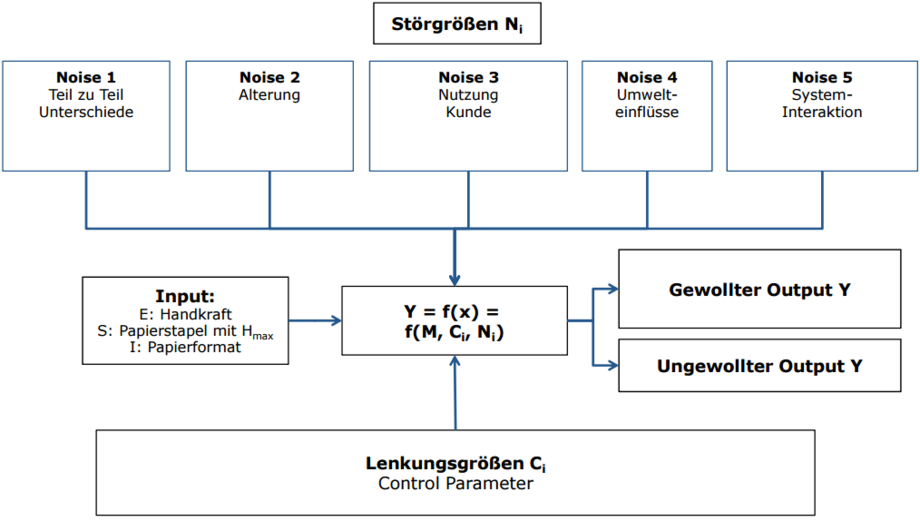

1. Definition of the system and identification ofinput and output parameter

- Transfer from Boundary Diagram resp. Interface Matrix (if applicable)

- Method can also be used for the sub-systems

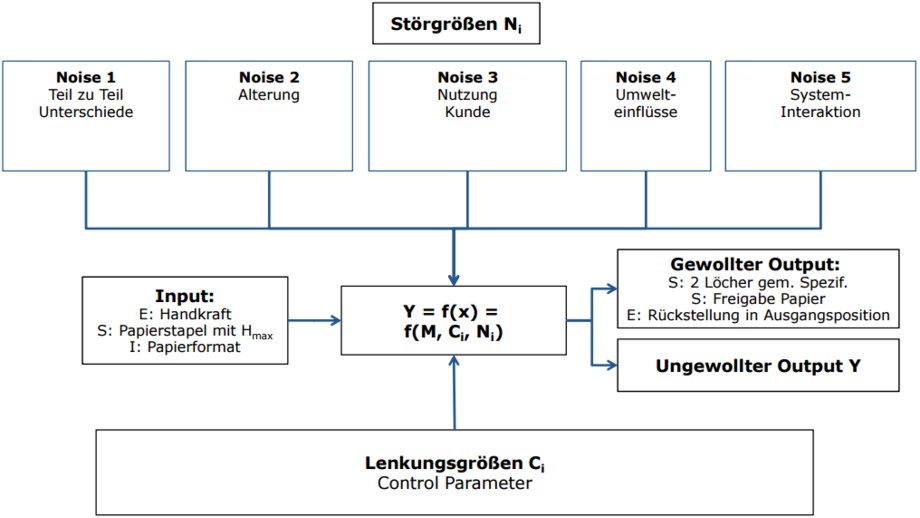

2. Description ofsystem function(s)

- Preferably technical, precise and quantifiable expression, relating to material-, energy and signal flows: “To convert manual force and movement into cutting force and movement“, “To convert paper without holes into paper with holes“

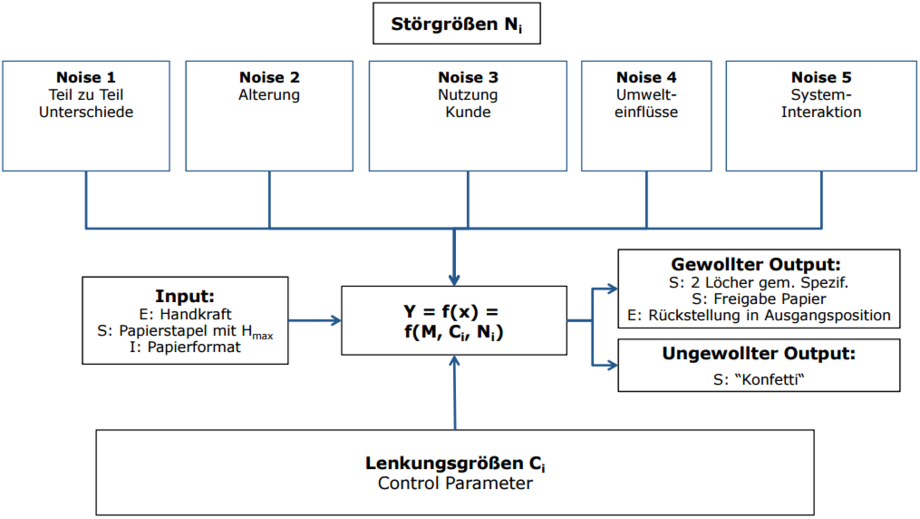

3. Systematic collection of potentialnoise parametersof the 5 (or more) categories

- Failure modes, root causes and preventive actions for FMEA can be derived from noise parameters

4. Systematic collection ofcontrol parameters

- These must appear in FMEA as product characteristics resp. process characteristics, or as system elements

- You can also extrapolate preventive measures from here