Tolerance Management

1. Objective (Why?)

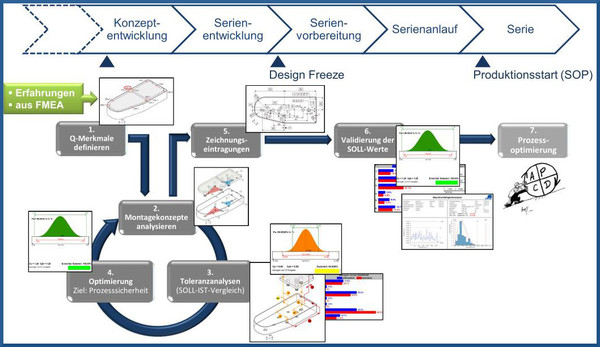

The FMEA provides impulses on existing risks and critical influencing factors with regard to quality targets. The task of tolerance management is to record these and systematically analyze them using statistical tolerance calculations. The resulting tolerance models are further and further detailed along the product creation process (PEP). This makes it possible to obtain reliable results at an early stage in the PEP as to whether a targeted assembly quality is achieved in a process-safe manner and which requirements the individual parts as well as the assembly have to fulfill for the target fulfillment.

2. Procedure (How?)

Corresponding to the functional connections (function network) and the error set, this is assigned wherever there is no or an inadequate statistical tolerance management. On the basis of the TM findings, optimization measures of a constructive nature and / or with regard to the assembly (sequence, devices, etc.) are initiated.

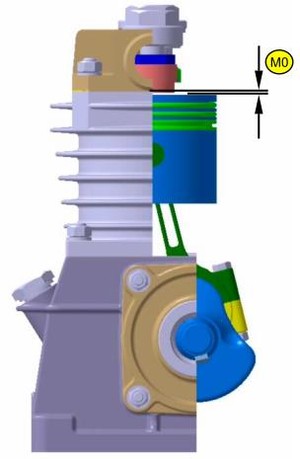

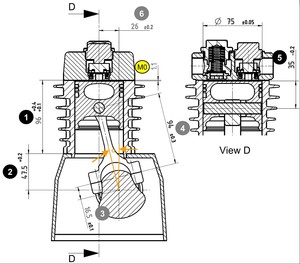

Example - Compressor

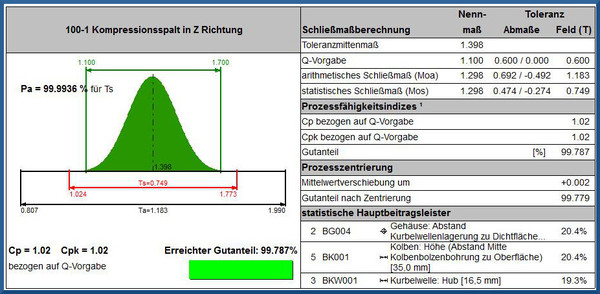

In the FMEA, the compression split [M0] was identified as a critical feature. To fulfill the function the following specifications are placed on the compression split:

N0 = 1,1 mm

Spezification Limits: +0,6 /0,0 mm

3. Result

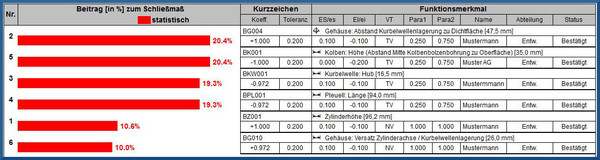

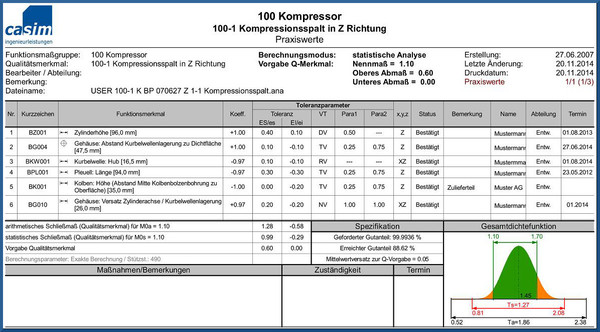

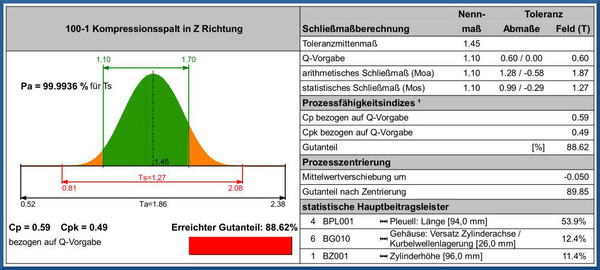

A tolerance model based on the statistical tolerance calculation is derived from the functional network of FMEA.

The desired quality can be achieved under the given circumstances, i.e. The currently applicable tolerances are not process-safe. The low values for Cp = 0.59 and Cpk = 0.49 clearly show this (Cp> Cpk> 1.33). Only a good 88% of all compressors would meet the necessary compression split. The "red light" underlines this visually.

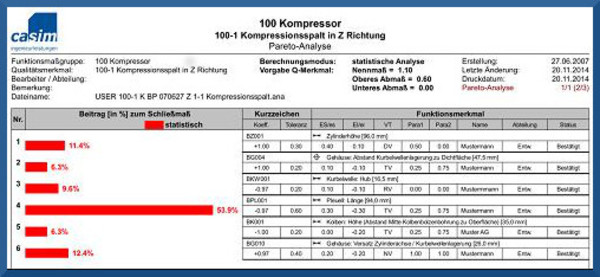

Optimization

The optimization potentials were identified in a subsequent optimization process using a contribution analysis and evaluated within the TM.

The planned and implemented measures are documented, tracked and concluded after completion in the FMEA. The FMEA serves as a tracking tool and records the measures taken. The effectiveness of the measures is demonstrated as part of the accompanying verification activities.